Process

Summary

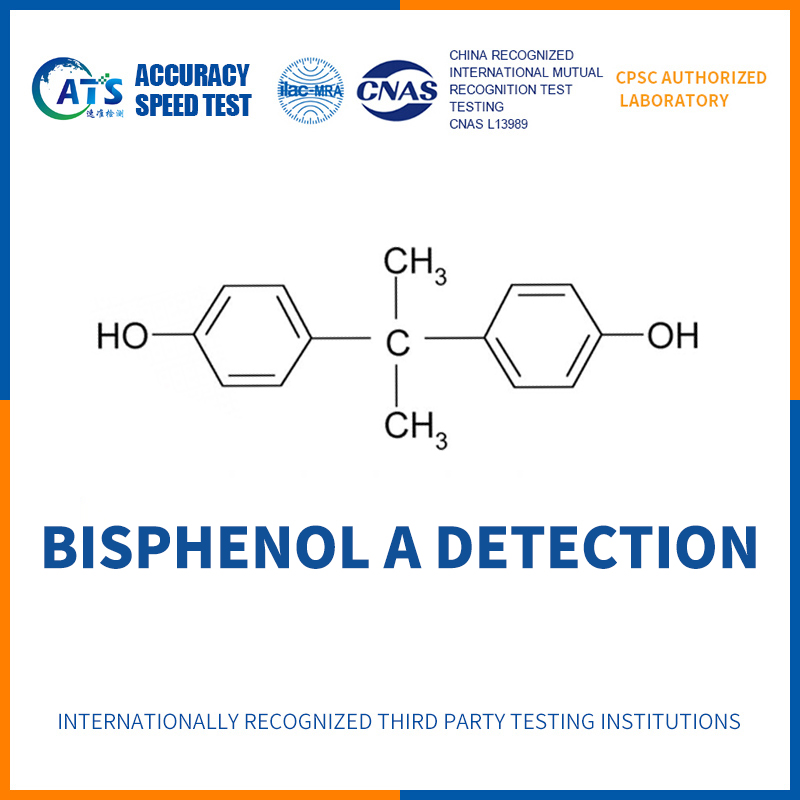

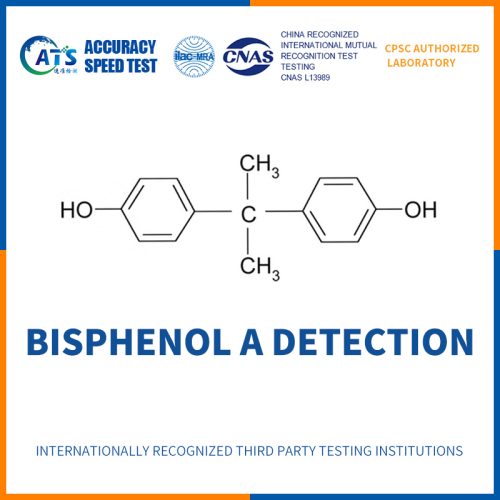

Bisphenol A, also known as BPA, is an organic compound with molecular formula c15h16o2. In industry, bisphenol A is used to synthesize polycarbonate (PC) and epoxy resin. Since the 1960s, it has been used to make plastic (milk) bottles, suction cups for young children, and inner coating of food and beverage (milk powder) cans. BPA is everywhere, from mineral water bottles, medical devices to the inside of food packaging. Every year, 27 million tons of plastics containing BPA are produced all over the world. But BPA can also lead to endocrine disorders, threatening the health of fetuses and children. Obesity caused by cancer and metabolic disorders is also considered to be related. The EU believes that bottles containing bisphenol A will induce precocious puberty. From March 2, 2011, the production of baby bottles containing chemical bisphenol A (BPA) will be banned.

National Bisphenol A Restriction Regulations

Sweden

In March 2013, the Swedish code published regulation SFS 2012:991, which prohibits bisphenol A (BPA) in food packaging coatings and coatings for children under 3 years old. The new regulation revised food regulation 2006:813 and will enter into force on July 1, 2013

Norway

The first to include bisphenol A in the restricted substances should be the Norwegian ROHS directive, which was originally scheduled to enter into force on January 1, 2008 and later extended due to the lack of consensus on many issues. Bisphenol A (BPA) is included in the 10 substances prohibited in consumer products

Canada

On October 18, 2008, Canada declared bisphenol A as a toxic chemical, thus becoming the first country in the world to list bisphenol A as a toxic chemical, and banned the use of bisphenol A in the production of baby bottles

USA

(1) Federal: proposed in March 2009 to ban the use of BPA in "reusable food containers" and "other food containers". The ban came into effect 180 days after its formal adoption

(2) Suffolk County, New York: the resolution announced on April 2, 2009 will enter into force in 90 days. Under this law, no one in Suffolk County may sell or provide for sale baby bottles and children's beverage containers containing BPA for children under the age of 3

(3) Illinois: as of July 1, 2010, no one may sell, offer, distribute, or offer for distribution a sports water bottle containing bisphenol A, or a children's food container for children aged 3 or under, whether or not the container contains food or beverages

(4) Maryland: it is stipulated that children's care products shall not contain bisphenol A or any other substances that cause cancer or are toxic to the reproductive system. At the same time, the manufacturer shall mark the products without bisphenol A. Any violation of the above provisions may be subject to a fine of up to US $10000

China

On May 30, 2011, the Ministry of health and other six departments announced that in view of the sensitive population of infants and young children, bisphenol A is prohibited from being used in infant milk bottles in order to prevent food safety risks and protect infant health.

Azo Compound Detection

Azo dyes (azo dyes, a class of organic compounds with aryl groups connected at both ends of azo group) are the most widely used synthetic dyes in textile and garment dyeing process. They are used for dyeing and printing of a variety of natural and synthetic fibers, as well as for coloring of paint, plastic, rubber and so on. Under special conditions, it can decompose and produce more than 20 kinds of carcinogenic aromatic amines. After activation, it can change the DNA structure of human body, cause lesions and induce cancer. Azo dyes are the largest category of dyes. In the process of production and application, about 10% - 15% of dyes are discharged into the environment without treatment, which may seriously affect the health of contacts. Therefore, azo wastewater must be treated harmlessly before discharge. Azo wastewater is considered to be the most harmless and effective method to decolorize the environment

Textile category

- Clothing, bedding, towels, wigs, false eyebrows, hats, diapers and other cleaning and sanitary products, sleeping bags

- Shoes, gloves, watch straps, handbags, wallets, briefcases, chair covers

- Textile or leather toys, toys with textile or leather clothing, synthetic dyes, organic compound dyes

- Consumer end use fabrics and yarns

- Decorative fabrics.

Carcinogenic Aromatic Amines

Aminobiphenyl, benzidine, 4-chloro-2-methylaniline, 2-naphthylamine, 4-amino-3,2 '- dimethylazo benzene, 2-amino-4-nitrotoluene, 2,4-diaminoanisole, 4-chloroaniline, 4,4' - diaminodiphenylmethane, 3,3 '- dichlorobenzidine, 3,3' - dimethoxybenzidine, 3,3 '- Dimethylbenzidine, 3,3' - dimethyl-4,4 '- diaminodiphenylmethane 2-methoxy-5-methylaniline, 4,4 '- methylene-bis (2-chloroaniline), 4,4' - diaminodiphenyl ether, 14,4 '- diaminodiphenyl sulfide, 2-methylaniline? 2,4-Diaminotoluene, 2,4,5-trimethylaniline, 2-methoxyaniline, 4-aminoazobenzene, 2,4-xylidine, 2,6-xylidine

Halogen detection

Halogen elements refer to group a elements, including fluorine (f), chlorine (CL), bromine (BR), iodine (I), astatine (at) and Ishida (TS), which are referred to as halogen for short. They exist in nature as typical salts and are salt forming elements. The elemental substances of halogen elements are diatomic molecules, and the changes of their physical properties are very regular. With the increase of molecular weight, the dispersion force between halogen molecules gradually increases, the color becomes darker, and their melting point, boiling point, density and atomic volume also increase in turn. Halogen has oxidation, and fluorine has the strongest oxidation. Halogen elements and metal elements constitute a large number of inorganic salts. In addition, they also play an important role in organic synthesis and other fields.

Routine Halogen Test Items

Fluorine (f), chlorine (CL), bromine (BR), iodine (I)

International regulations

IEC 61249-2-21

Printed circuit board materials and other interconnection structures - Part 2-21: clad and non clad reinforced substrates, flame retardants (vertical combustion test), copper clad halogen-free epoxy woven E-type glass fiber reinforced laminates (specify the halogen of all materials of circuit boards)

- Chlorine limit ≤ 900ppm

- Bromine limit ≤ 900ppm

- Bromine + chlorine content ≤ 1500ppm

International printed circuit association standard ipc4101b

- Chlorine limit ≤ 900ppm

- Bromine limit ≤ 900ppm

- Bromine + chlorine content ≤ 1500ppm

Japan printed circuit board Association (jpca-es-01-1999)

- Chlorine limit ≤ 900ppm

- Bromine limit ≤ 900ppm

Nickel release detection

Nickel is a metallic element that is silvery white, hard, malleable and ferromagnetic. Nickel is insoluble in water and forms a dense oxide film on the surface in humid air at room temperature, which can prevent the continuous oxidation of bulk metal. It is not easy to react with concentrated nitric acid and can be dissolved slowly in dilute acid

Nickel is the most common sensitizing metal element. Nickel is released through some nickel containing materials and will be absorbed by the skin after long-term contact with the skin, resulting in allergy to some individuals; About 20% of people are allergic to nickel ions, and the number of female patients is higher than that of male patients. When in contact with the human body, nickel ions can penetrate into the skin through pores and sebaceous glands, resulting in skin allergy and inflammation. Its clinical manifestations are dermatitis and eczema. Once sensitization occurs, nickel allergy can last indefinitely

At present, in clothing, jewelry and other daily necessities exported to Europe, if there are metal accessories containing nickel in their material composition, it is generally required to detect the standard release of nickel

Nickel release instruction

Because some people are allergic to nickel, the EU and China have made provisions on the content and release of nickel in products in long-term contact with human skin and products piercing ears or other parts of the body: the EU has adopted nickel Control Directive 94 / 27 / EC to unify the laws of Member States, which is used to control the use of nickel in products in direct or long-term contact with skin, In 2004, the EU passed the EC Directive to amend all pierced objects that pierce the human body and implemented it from September 2005. The EC no longer requires the total content of nickel in accessories that pierce ears or other parts of the body, but requires that the release of nickel shall not exceed 0.2ug/cm2/week

Applicable products: Children's products, including metal rivets, buttons, fasteners, zippers, metal plates and markers on toys or children's clothes; Necklaces, bracelets, watch cases, watch straps, metal spectacle frames, metal shells and metal buttons of consumer electronic products (headphones, MP3, digital cameras, etc.)

Principle of nickel release detection

Put the test object into the artificial sweat test solution for one week, and test the concentration of dissolved nickel (Ni) in the solution by atomic absorption spectrometry, inductively coupled plasma spectroscopy or other appropriate analytical methods. The amount of nickel released is expressed in micrograms per square centimeter per week (UG / cm2 / week)

Detection method

EU

Nickel emission test of products in direct and long-term contact with skin (EN1811: applicable to products without electroplating coating); Test for measuring nickel release from electroplated coated articles after catalysis and wear (en12472: products applicable to electroplated coatings)

China

In 2002, gb11887-2002 regulations on purity and nomenclature of jewelry and precious metals were promulgated and implemented. Requirements:

1. The content of nickel in the total mass of products used for perforation of ears or any other part of the human body and removed or retained during the healing of perforated wounds must be less than 0.05%

2. The nickel release of products in long-term contact with human skin must be less than 0.5ug/cm2/week

GB/T 19719-2005 GB28485-2012

Nickel Release Limit Requirements

Due to the different requirements on nickel release between China and the EU, the products to be tested can be divided into the following two main categories, and the corresponding limit requirements are as follows:

1. It is used for perforation of ear or any other part of human body, and products removed or retained during perforation healing,

1.1 China: the content of nickel in the overall quality must be less than 0.05%

1.2 EU: the release of nickel shall not exceed 0.2ug/cm2/week

2. The amount of nickel decoration of products in long-term contact with human skin must be less than 0.5ug/cm2/week.